Description

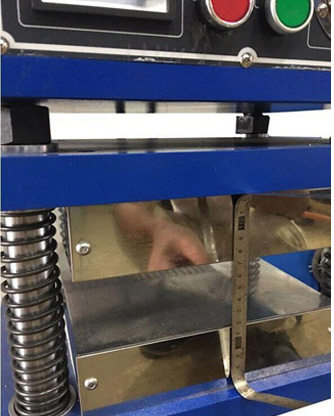

Vulcanizing press machine is also known as Lab curing press equipment ,it is one laboratory equipment, applicable to R & D in laboratory,used to make all kinds of vulcanizing mould,rubber products,plastics products,and testing pieces used by institute, university & college.

lab vulcanizer machine is one equipment used for vulcanizing various rubber and plastic products, it heat rubber material with sulphur ,accelerator .This lab press machine is used to produce vulcanizing parallel adhesive type, such as conveyor belt,driving belt, by way of presseing these raw material,it is finally foamed as rubber, plastic,thermosetting plastic(bakelite) and other plastic products.

Vulcanization is a process which is carried for curing of elastomers.The raw material is placed in the mould between the electric heating plate .The hydraulic systems of vulcanizing hydraulic machine would give mechanical pressure to the elastomers ,your raw material would be pressed and heated through thermic oil or electricity, finally the raw material is formed for testing and mass production.

The vulcanizing press machine has been developed to hot vulcanize all types of rubber, for example, EPDM, NBR, SBR CR, NR and without retooling the Lab curing press equipment can also be used to splice silicone profiles.

The Vulcanizing press machine is easy to operate, the operator can uses the foot-pedal to close and open the tools. Heat and time are easy to change in the display.

| Capacity | 20T,25T ,30T |

| Temperature Range | R.T.~300°C |

| Temperature Controller | LED digital display, key setting input, numerical display output |

| Temp Accuracy | ±2℃ |

| Heating Method | Cartridge Heaters |

| Warm-Up Time | 0 ~ 200 ° C takes about 25 min |

| Timer | LED digital display 0.1S ~ 99M~ 9.9h curing time can set the alarm |

| Press Platen Dimensions | 350×350×40mm,customized |

| Press Layers | Single layer, heating up and down mould pressing plate |

| Clamp Distance | 60mm |

| Pressure Gauge | 0~350kg/cm2 |

| Working Power | 4KW |

| Dimension | 400x450x1000(W×D×H)mm |

| Weight | 195kg |

| Power Supply | 1∮,220V,15A(Customer prepare power connection) |

Reviews

There are no reviews yet.